It is widely understood that test and measurement tools enable the defense industry to identify vulnerabilities and weaknesses in electronic systems and networks through comprehensive testing and analysis. By simulating various attack scenarios and conducting communication tests and measure emersion, units can assess the resilience of their communication and identify potential points of failure.

With a rapidly evolving environment, it is becoming increasingly apparent how important it is for the industry to be able to conduct in-situ tests as and when required. In this blog, we outline just a few of the reasons why.

1. Defense is operating in a unique environment

The defense environment is one of extremes. Not only are military personnel often required to operate in remote environments, they are frequently doing so on the move. At the same time, the environment and scenarios can change rapidly, especially in a battle scenario. And yet, while a drop in connectivity is not desirable for any user group, in the defense sector, lives are literally depending on it. Military operations teams need to be able to communicate with confidence, navigate with certainty, perceive an operational area with lucidity, and engage with accuracy whether during peace, crisis, or conflict.

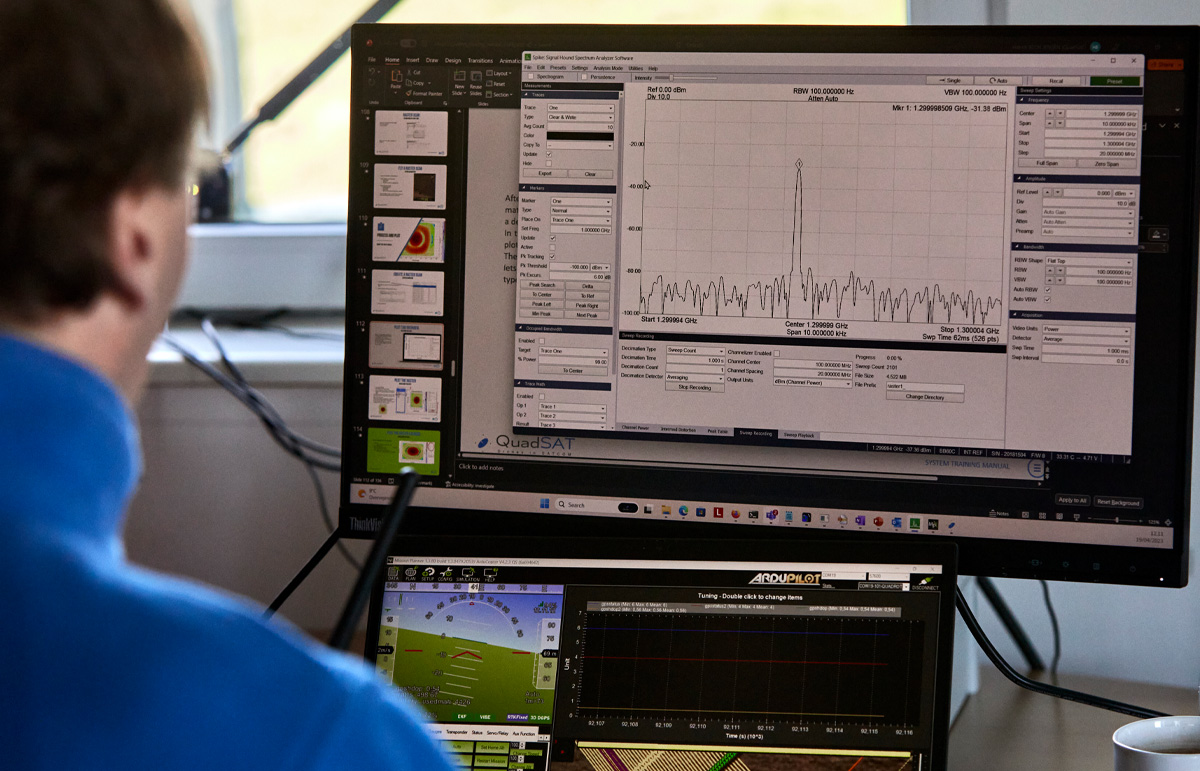

All of this means that the defense industry needs to be assured that its RF and electromagnetic equipment is operating seamlessly at all times, whatever the environment. The defense industry needs to both have ways to quickly, yet accurately test on the spot before questionable systems are sent into combat, as well as enabling troops to test in-situ as and when errors arise. This means errors can be pinpointed and resolved rapidly, before any major impact is suffered.

2. New technology is being introduced rapidly

The defense sector is a big adopter of new technology and with good reason. New innovations are crucial for delivering a crucial operational advantage. However, with all new technology there is always a certain level of risk that it might not operate as it should once in the environment. Testing in a dedicated test center is important before deployment but once out in the field, other factors might influence how it actually performs in real-life. Any errors with new equipment can cause setbacks and delays and makes it harder for defense to adopt this new technology.

Being able to train in a real operational environment enables military personnel to determine how that technology will respond before using it in a more critical situation. Rapid in-situ testing procedures also make it possible to speed up the adoption of new technology, helping the defense sector to more easily embrace innovations as they happen.

3. Threats are real and serious

Of course, one of the biggest things that sets the military apart is the simple fact that it is constantly facing very real and serious threats. From cyberattacks, anti-satellite launches, orbital threats, spying, laser illumination, to sabotage, jamming and spoofing, milsat systems are facing a raft of constantly evolving threats that it must protect its systems against. Electronic attacks have become increasingly sophisticated and are one of the most significant threats to military satellite systems. These attacks are hard to grasp in an operational environment and it can be challenging to measure and understand the real impact.

Being able to quickly test in-situ means operational teams can determine presence and impact of these kinds of attacks and take measures to get systems back online as quickly as feasibly possible. Investing in training and measuring equipment can empower defense system operators to analyze real threats and identify critical weak points and indicate hostile opportunities. Advanced diagnostic tools can not only detect ongoing attacks but also help to predict and prevent potential threats before they materialize.

How Quadsat is revolutionizing testing for the defense industry

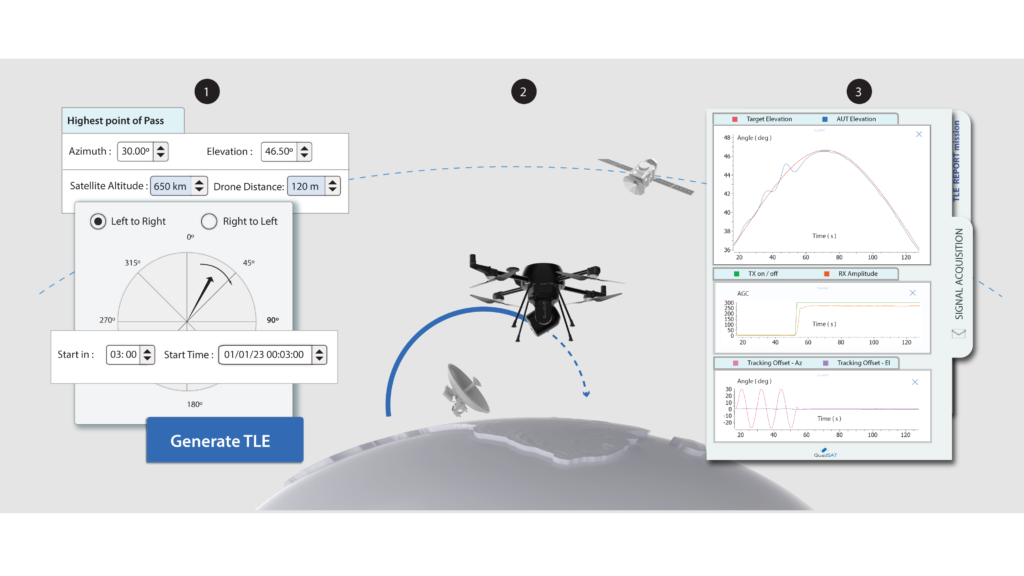

Quadsat’s UAV-based testing solutions are helping the defence industry to flexibly, and cost-efficiently, perform regular in-situ testing. Quadsat can make the invisible threats visible. This means that the defense sector can better optimize signal performance while safeguarding mission-critical communications.

Come and see the team at Govsatcom (booth 28) to learn more. Get in touch to book a meeting.